In the fast-evolving world of material handling, the selection of a suitable lifting beam is crucial. John Smith, an industry expert from LiftTech Solutions, once said, "Choosing the right lifting beam can make or break your operation." His words resonate deeply within the field, highlighting the importance of efficiency and safety.

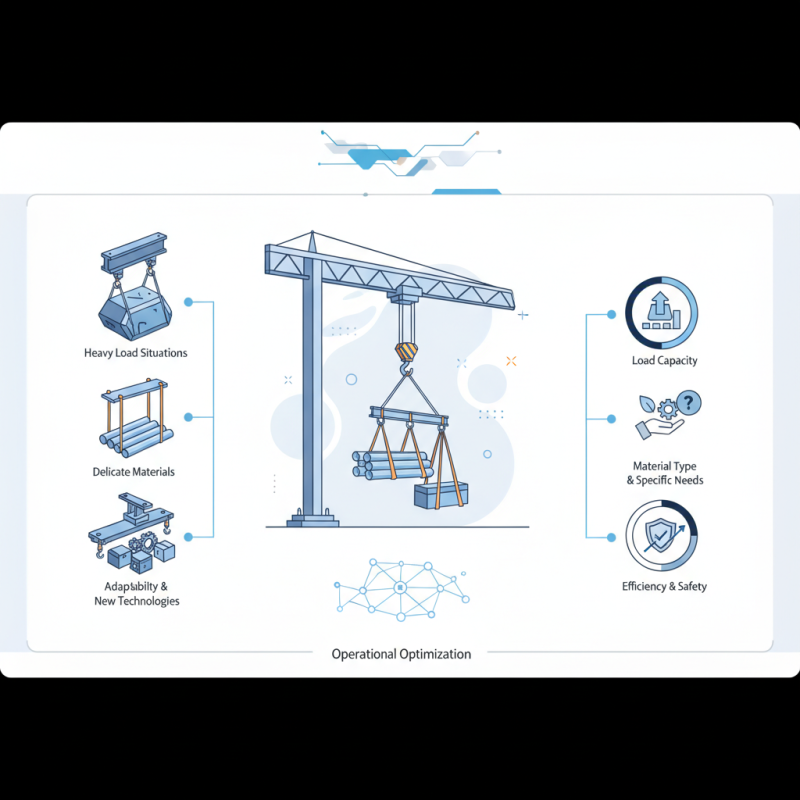

Lifting beams come in various types, each designed for different applications and environments. For instance, some beams excel in heavy load situations, while others are perfect for delicate materials. Many companies face challenges when choosing the appropriate type. The wrong lifting beam can lead to accidents, delays, or equipment damage. Understanding the specific needs of your operations is vital.

Moreover, innovation in lifting beam design is constantly emerging. Companies must adapt to new technologies and methods. While many are quick to adopt, not all fully understand the implications. When selecting a lifting beam, factors like load capacity and material type must be considered. Reflecting on these choices can significantly enhance operational efficiency and safety in material handling.

Lifting beams play a crucial role in material handling by distributing loads evenly. In 2026, various types of lifting beams will enhance efficiency in warehouses and construction sites. These beams can be adjustable, fixed, or spreader types, adapting to different loads and tasks.

When choosing a lifting beam, consider its weight capacity. Beams that seem ideal might not handle maximum loads effectively. Safety features are also vital. Ensure that the lifting beam has secure locking mechanisms. Check for wear or damage regularly to avoid unexpected failures.

Integration with existing systems is important. Some beams work better with specific hoisting equipment. Connecting incompatible devices can lead to inefficiencies. Test all components before full use. Make gradual improvements to avoid complete overhauls. Efficiency requires small adjustments rather than big changes.

When it comes to efficient material handling, lifting beams play a crucial role. They are designed to distribute loads evenly, reducing stress on both the beam and the lifting equipment. A key feature of effective lifting beams is their adjustable width. This allows users to customize the setup based on the load's dimensions. Additionally, having multiple attachment points can enhance stability and facilitate more complex lifting tasks.

Weight capacity is another vital element. Each beam should have clear specifications regarding its maximum load. It’s essential to regularly evaluate whether the equipment meets the demands of various materials. Overloading can lead to accidents, and safety should never be taken for granted. Furthermore, easy maneuverability is often overlooked. Some beams are heavy and difficult to position, making them less efficient for quick lifting tasks.

Another aspect to reflect on is the material used in the construction of lifting beams. Steel is durable but can be cumbersome. Meanwhile, aluminum offers lightweight options but may not support heavier loads. A balance between weight and strength is necessary for optimal performance. Regular maintenance checks and inspections can ensure they remain in good working order, but users often neglect this. Proper training for operators is equally important to guarantee safety and efficiency.

When choosing lifting beams for material handling, safety should always be a priority. Data from the Material Handling Industry of America (MHIA) shows that over 20% of workplace accidents involve improper lifting equipment. A lifting beam must suit the load type and weight. Consider the beam's load capacity. Underestimating it could lead to severe accidents.

Tips: Always inspect the lifting beam before use. Look for signs of wear or damage. A small crack could lead to failure during operation.

Proper training is essential for operators. 35% of incidents arise from operator error. Regular training sessions can bridge this gap. Clear communication among team members is vital during lifts. Safety protocols should be prominently displayed at job sites.

Tips: Encourage teamwork during lifts. A coordinated approach can reduce risks significantly. Be aware of the load's center of gravity. It impacts stability. If a lift feels unsteady, stop immediately. Make adjustments before continuing.

| Lifting Beam Type | Load Capacity (tons) | Length (ft) | Material | Safety Features |

|---|---|---|---|---|

| Standard Lifting Beam | 5 | 10 | Steel | Safety Locking Mechanism |

| Adjustable Lifting Beam | 10 | 12 | Aluminum | Load Cell for Monitoring |

| Heavy-Duty Lifting Beam | 15 | 15 | High-Strength Steel | Welded Reinforcement |

| Crane Lifting Beam | 8 | 14 | Composite Materials | Emergency Stop Switch |

| Custom Lifting Beam | Varies | Varies | Steel/Aluminum | Certification Compliance |

Lifting beams play a crucial role in various industries by enhancing material handling processes. For example, in construction, lifting beams simplify the movement of heavy loads. According to the Material Handling Industry of America, an efficient lifting beam can reduce handling time by up to 25%. This improvement leads to significant cost savings.

In manufacturing, these tools are essential for assembly lines. Many operations can become bottlenecked due to inefficient lifting methods. A study by the National Safety Council shows that improper lifting causes over 30% of workplace injuries. Using appropriate lifting beams minimizes risks and enhances safety.

However, implementing lifting beams isn't always straightforward. Industries face challenges like load distribution and beam design. Many organizations overlook these aspects, leading to inefficiencies. Continuous training and evaluation are needed to adapt to changing demands. Some companies realize too late that proper equipment choices are vital for success.

As the demand for efficiency increases, lifting beam technology is evolving rapidly. Future trends indicate a shift towards lightweight materials. These advancements will reduce energy consumption. The integration of smart sensors in lifting beams will enhance monitoring. Real-time data can help improve safety and operational efficiency.

Lifting beams are becoming more customizable. Users will have options tailored to specific tasks. This flexibility allows for a better fit in various environments. Modular designs may also become popular. They can easily adapt to changing needs.

Tips: Ensure the weight distribution is even. Improper loading can lead to accidents. Regular maintenance checks can prolong beam life. Evaluating needs before purchasing is crucial. Not every beam will suit every job.